Measure length and angle first, and the seamless steel tubes are 100% hand-made.

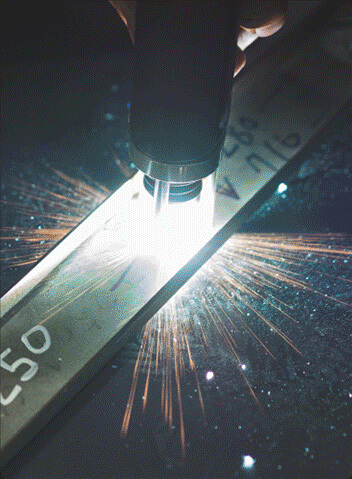

We welded at each important joint to make the structure more stable and durable.

Inconspicuous wiping prevents industrial iron filings from entering the hydraulic circuit.

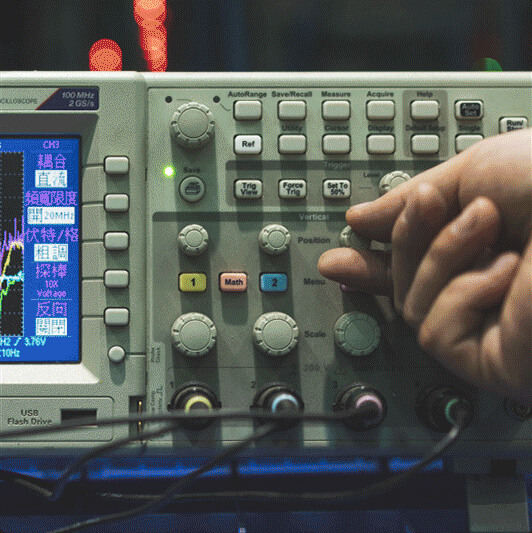

Using professional oscilloscope, we strictly demand the stability and repeatability of our injection molding machine.

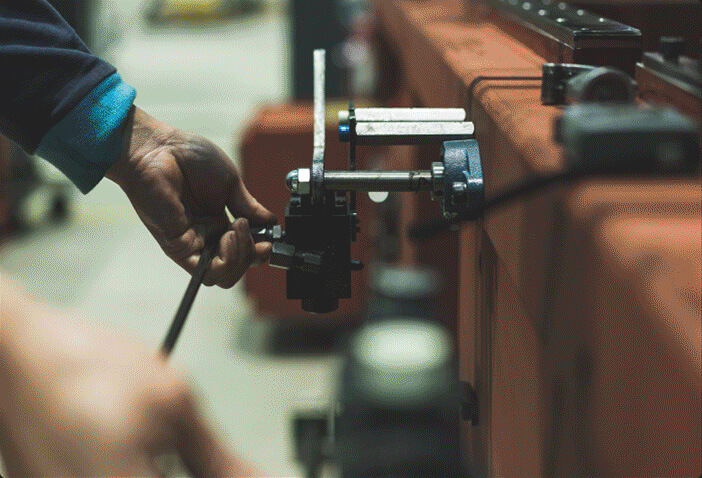

Tap the barrel nut until it is tightened.

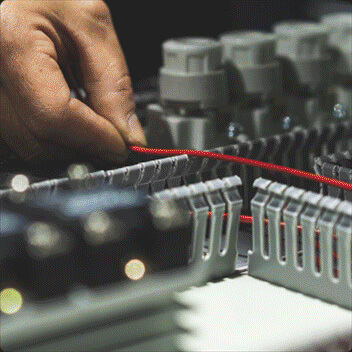

Distributing each line well is to reduce the electrical pulse disturbance.

Every measurement is actually recorded and saved.

Tap the barrel nut until it is tightened.

Tighten the screws diagonally. The use of torque wrench is the focus of each installation.

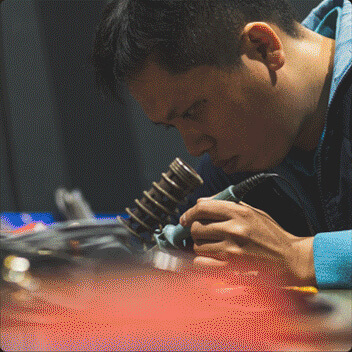

Inspect carefully after welding to avoid any miss.

The screw-charging motor is asked to be flush tightly and evenly with the end surface of the motor base, and then we tighten the set screws.

Installation of hydraulic ejector cylinder on the movable platen.

Installation of hydraulic ejector cylinder on the movable platen.

Before machining, it is necessary to measure and draw lines frequently.

It's not just a small nail, but the one that we ask to be accurate and precise.

Regular measurement of aperture, outer diameter, depth, length, hardness, parallelism, perpendicularity and angle of chamfer.

Screw, check ring and screw-tip are assembled and tested.

The most important parts are controlled by ourselves to ensure stable quality.

It's not just a small nail, but the one that we ask to be accurate and precise.